Multi-Tool Maintenance: A High-Level Guide

Multi-Tool Maintenance: A High-Level Guide

Your multi-tool is a lifeline for daily living, helping you meet the sundry challenges of the day head-on. But, just as your multi-tool takes care of you, you should take care of it. Beyond cleaning and rust prevention, here are a few ways to keep your multi-tool in fighting shape.

Keeping It Clean

Keeping your multi-tool clean is your first line of defense against corrosion and wear, and the single most important aspect of multi-tool maintenance. First things first, never put your multi-tool away either dirty or wet. Whether it’s covered in mud, sand, salt spray, grease, or blood, make sure to thoroughly clean and dry it before you store it. The most basic way to clean off a multi-tool that’s seen a lot of use is with clean, soapy water. A quick rinse off with soapy water is good; but after you’re done, rinse thoroughly to remove all soap residue, then set somewhere warm and dry. It must be thoroughly dry before storing because you don’t want any moisture to get trapped in any of the joints. This will cause it to rust.

Keeping your multi-tool clean is your first line of defense against corrosion and wear, and the single most important aspect of multi-tool maintenance. First things first, never put your multi-tool away either dirty or wet. Whether it’s covered in mud, sand, salt spray, grease, or blood, make sure to thoroughly clean and dry it before you store it. The most basic way to clean off a multi-tool that’s seen a lot of use is with clean, soapy water. A quick rinse off with soapy water is good; but after you’re done, rinse thoroughly to remove all soap residue, then set somewhere warm and dry. It must be thoroughly dry before storing because you don’t want any moisture to get trapped in any of the joints. This will cause it to rust.

Protecting It Against Corrosion

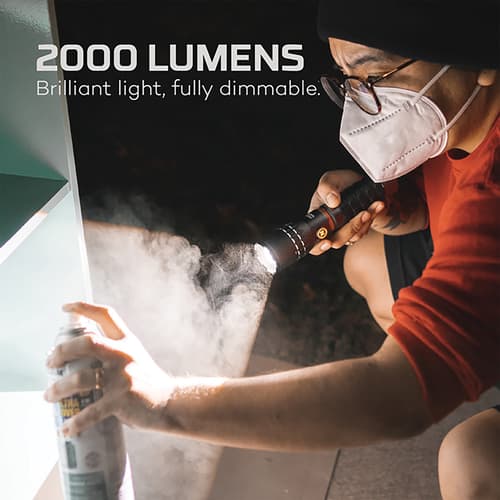

As stated, keeping a multi-tool clean is your first line of defense against corrosion, but even so, there are additional precautions you can take to help prevent rust from seizing the works. After keeping the tool clean, the best thing you can do to prevent rust and corrosion is to seal it off to the elements. There are numerous treatments you can use for this, such as the aforementioned WD-40 which will drive out oil, but oils like machine, tool or gun oil are equally as effective and longer lasting (WD-40 is effective at driving out moisture but evaporates pretty quickly). Another component of protecting your multi-tool against the ravages of corrosion has to do with storing it properly. Even a well-maintained multi-tool made with a high-end corrosion resistant alloy will rust if it’s stored somewhere hot and humid. The rule is this: store it somewhere cool and dry - most importantly dry, as chronically wet conditions can and will result in corrosion, even of highly rust-resistant alloys.

Keeping the Joints Lubricated

Almost all multi-tools sport a hinged, folding, or articulated design of some sort or other. Though this is not always the case, keeping the joints of an articulated tool lubricated will help prevent premature wear, hardware seizures, and other related problems. A light machine or gun oil like Hoppe’s Gun Oil or Rem Oil will do the trick. Just a drop on any hinged components should help keep them limber and it will offer the added bonus of keeping corrosion at bay. There is one caveat here, and it’s that you should use as little oil as possible for the purposes of lubrication. Oil, while it protects against rust and lubricates, is also sticky and will attract dirt and dust which conversely can accelerate wear. So remember, just a drop does it.

Keeping the Blade Sharp

There is a saying that goes like this “a sharp knife is a safe knife” and for what it’s worth, it’s true. It might sound counterintuitive, but the truth is, a dull knife requires you to use more force when in use. That can result in straining and slipping. A sharp knife will cut cleanly and is less likely to incur the risk of a slip. The solution is simple. If your multi-tool has a blade, make sure you keep it sharp and in working order. You don’t need to keep it like a razor, but any time you start to notice it’s getting dull, give it a few passes on a bench stone or a pocket stone to bring it back up to snuff and you should be good to go.

Tightening the Fasteners

One last recommendation for basic multi-tool maintenance. Some multi-tools are fashioned with rivets, but the vast majority are held together by small threaded fasteners - that is, screws. Over time, and with use, these fasteners can work loose and even fall out. The former case is bad enough but the latter is something you definitely want to avoid because if you lose a fastener it’s only a matter of time before the whole tool falls apart. Worst of all, it’s difficult, even next to impossible, to get compatible fasteners for most commercially available multi-tools. Some manufacturers that are reputable may sell parts but for the most part if you lose one you’ll be out of luck. Therefore, the best way to deal with this potential issue is to prevent it at the source. Make sure to periodically inspect the multi-tool for loose fasteners, and tighten them as needed. This will help prevent a much bigger potential headache down the line.

Here for a New Multi-Tool?

If you’re in the market for a new multi-tool for your workbench, bugout bag, or just for your back pocket, check out what we offer here at CH KADELS. We carry a wide range of high quality multi-tools that offer a great deal of value and which will prove indispensable in the field. Just make sure you properly care for your new tool, according to the maxims advised in this article.