51411

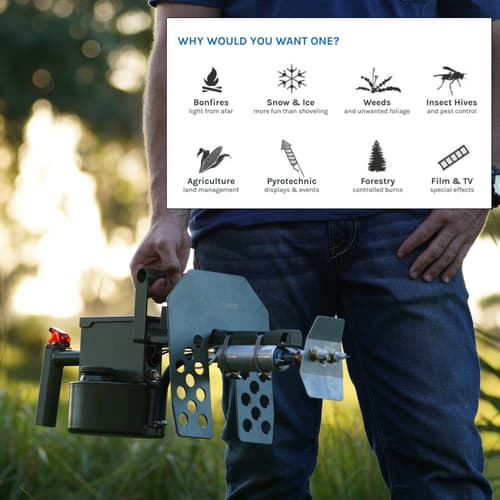

Pulsefire Long Range Torch - Flame Thrower, Shoots Flame 25-Feet, 1/4-Gallon Tank, Arc-Ignition, Rechargeable Battery

USD

0.0

null

BUDK

Camping Gear

Fire Starters

null

null

null

599.99

$599.98

Price reduced from

$749.99

to

51370

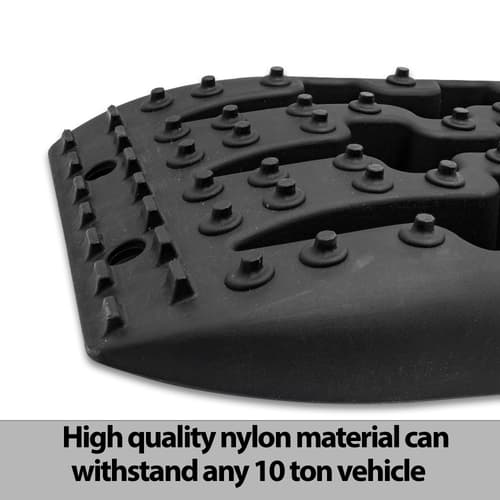

Off-Road Recovery Traction Boards - Set of Two Heavy-Duty Tire Grabbers - 42"X12"

USD

0.0

null

Chkadels

Best Survival Gear

null

null

null

129.99

50721

Night Watchman Solar Street Light - 120 LED Lights, 6000 Lumens, 8000 MAH, ABS Housing, Polycrystalline Solar Panel, Metal Arm

USD

0.0

null

Night Watchman

Survival Gear

Lights

null

null

null

89.99

44761

RAMPAGE® Portable Car Battery Jumper And Power Bank With Case - 8,000 MAH, Battery Clamps, Home And Car Adaptor, USB Multi-Head Cable

USD

0.0

null

BUDK

Survival Gear

null

null

null

79.99

47743

Russian Civilian GP-5 Gas Mask And Bag - Lightweight, Full-Coverage, Grey Rubber Construction, Sealed Eye-Pieces, Includes Filter

USD

0.0

null

BUDK

Survival Gear

Military Surplus

null

null

null

19.99

51903

Drifter9 142 Piece Survival Kit

USD

0.0

null

Chkadels

Survival Gear

Survival Kits

null

null

null

62.99

51259

Spartan Wool OD Anorak Jacket With Hood - 80% Wool Construction, Hand-Warmer Pocket- Size XL

USD

0.0

null

Chkadels

5 Star Rated

null

null

null

59.99